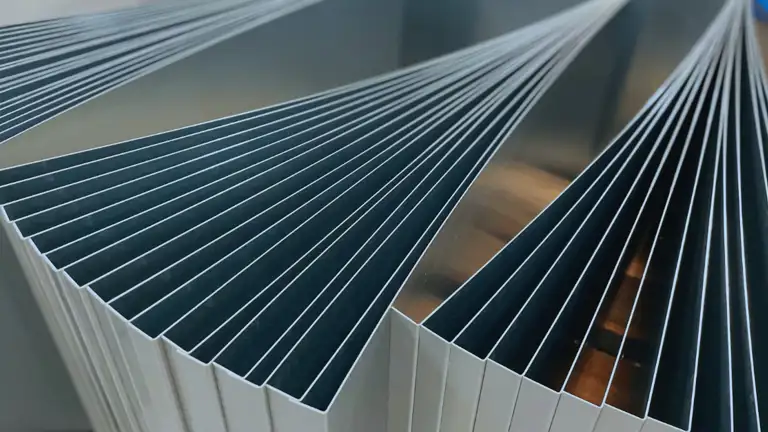

When space is limited but the need for chip and dust extraction is high, Aagaard’s bag emptying filters are a strong choice. They are compact, reliable, and easy to maintain – ideal for smaller systems with limited airflow.

How bag emptying works

Bag emptying filters extract dust and particles from the air and collect them in a sealed container. The cleaned air can be returned to the production area, improving energy efficiency. The system is easy to service, and the filter media can be quickly cleaned or replaced as needed.

Why many choose Aagaard

Our bag emptying filters are designed to support a healthy and safe working environment. We understand the importance of reliability and adaptability in industrial processes. With years of experience in dust filtration, Aagaard delivers solutions tailored to your specific needs.

Discover the benefits of bag emptying filters

Efficient chip handling with minimal maintenance and maximum flexibility.

Space-saving design:

Compact dimensions make it easy to integrate the filters into existing setups – even in tight spaces.

Efficient dust collection:

Effectively removes fine dust and particles, improving air quality.

Simple and reliable:

Few moving parts mean lower wear and high reliability in daily operation.

Flexible configurations:

Available with various container types, including steel bins – tailored to industrial requirements.

Where are Aagaard bag emptying filters used?

Woodworking

Plastics industry

Recycling sector

Contact Us

At Aagaard, you’ll meet people who understand your production. We have many years of experience delivering solutions that work – even when needs are complex.